Product Detials

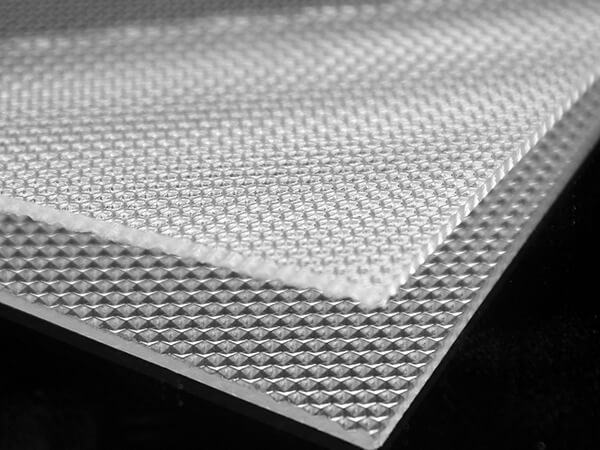

Thickness: 2mm-35mm

Specifications: 1220x1830mm, 1220x2440mm

Other sizes can be consulted and customized

Product Details

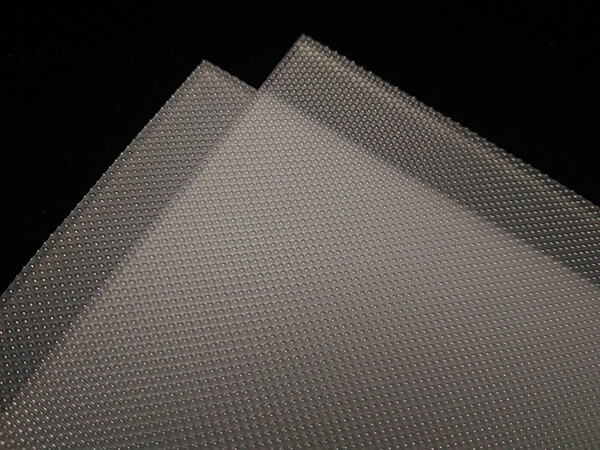

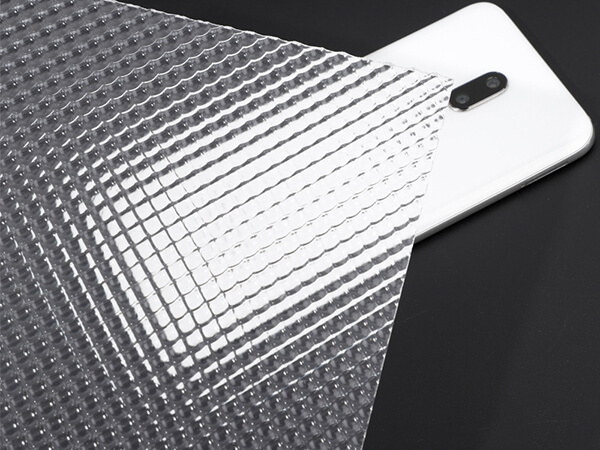

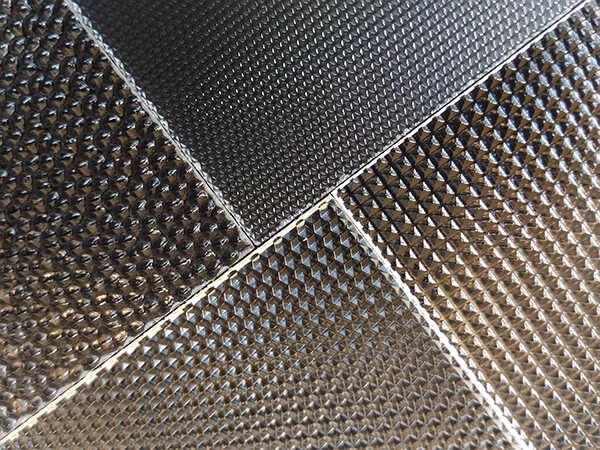

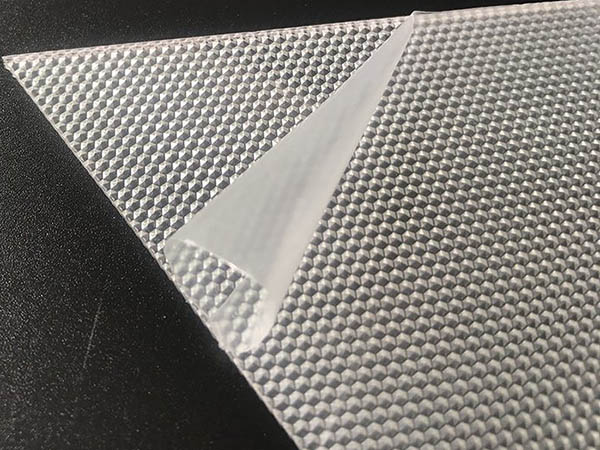

Light diffusing acrylic sheet principle for the use of nanoscale microbead light diffuser and optical acrylic (PMMA) or polystyrene (PS) ene substrate refractive index is different, when light through these different refractive index medium, will produce many penetrating refraction, as well as reflection, scattering phenomenon, so as to change the path of light, light source becomes evenly dispersed, point light source into surface light source, Enlarges the luminous surface, and makes the light softer, achieves the purpose of uniform light and light transmittance. At the same time to meet the requirements of various fog values and transmittance, and in the case of ensuring high transmittance and reducing light decay, custom cut plexiglass light diffuser sheet has a good light source masking effect.

COLOR CHAT:

(1)Good light diffusion effect

(2)Advanced visual perception

(3) Good impact resistance

(4) Light material

(5) Easy to process

(6)Good weather resistance

(7)Safety eye protection

|

Specific Gravity: |

1.2g/cm^3 |

|

Water Absorption: |

0.3% |

|

Vicat Softening Point: |

115°C |

|

Flammability: |

HB |

|

Elongation at Break: |

4.5% |

|

Izod lmpact Strength: |

2 kJ.m^-2 |

|

Electrical Strength: |

15 kV.mm^-1 |

|

Light transmission(clear sheet): |

92% |

|

Refractive Index: |

1.49 |

|

Rockwell Hardness: |

100 M scale |

|

Tensile Strength: |

75 MPa |

|

Flexural Strength: |

120 MPa |

|

Flexural Modulus: |

3200 MPa |

|

Surface Resistivity: |

>-10^14 Ω.m^-2 |

Light diffusing plastic is ideal for a range of scenarios, including:

(1)Photographs

(2)Menu boards

(3)Retail signage

(4)Channel letters

(5)Cabinets

(6)Other signage whether indoor or out

(7)Considerations When Choosing Light Diffusing Plastics

Do you have questions about our plastics products?We have the appropriate answers.